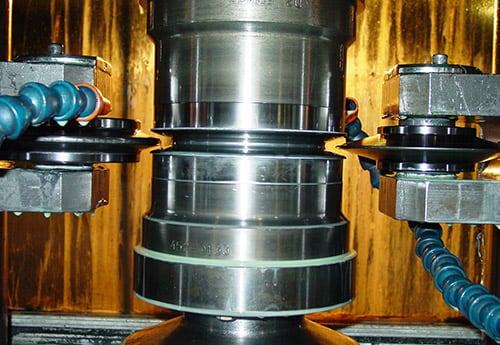

Scag® mowers feature split-steel pulleys for increased strength and reliability, and reduced wear on pump and cutter-deck drive systems. Split-steel pulleys are lighter in weight and stronger than cast iron. They are also stronger than stamped pulleys.

As split-steel pulleys are made from a single piece of steel, no balance holes are required, unlike a cast pulley which must be balanced and drilled. These drill points for balancing can create weak points.

The reduced weight (less rotational inertia) of the pulleys makes it easier for blades and other drive components to rotate up to speed. They also allow the electric clutch brake to stop the cutter blades faster with less wear on the clutch rotor and armature. In short, the split-steel pulley design adds to the life of drive components, increases product reliability and reduces maintenance time and cost. Features include:

- Stronger than cast-iron pulleys.

- Stronger than stamped pulleys.

- Lighter weight than cast-iron pulleys = less wear and tear on the drive systems.

- No extra balance holes required; pulley is balanced.

- Retains the use of taper-lock hub design for easy servicing.

- Black-oxide coating for reduced corrosion.