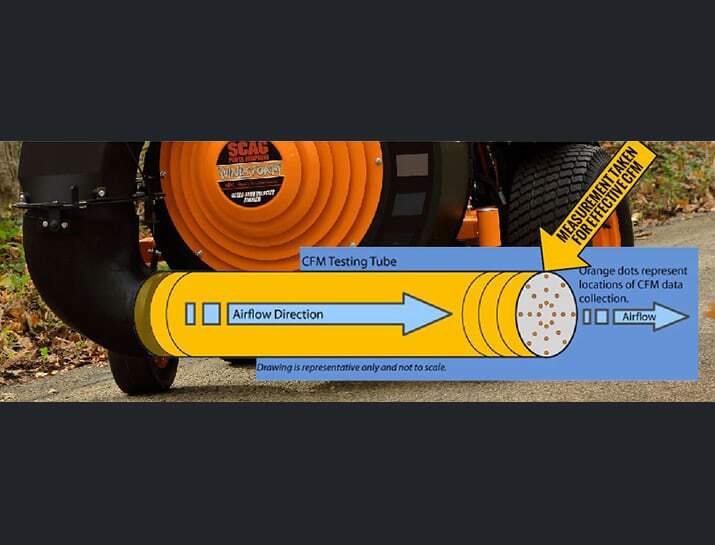

Effective CFM: A calculation obtained by applying accepted engineering methods of measuring overall average airflow volume, this is the default figure published by Scag® for all its blowers and truck loaders.

Here’s how we collected the published CFM data on Scag products. An accepted engineering method of collecting CFM data is to take multiple readings at a distance of approximately 10 times the diameter of the output tube. For example, if the output tube is 6″ in diameter, we would extend the tube about 60″ and take readings at the end of that tube. This is a good method as it gives the fast moving, turbulent air some time to settle down for more consistent, real-world, non-exaggerated readings.

Depending on the diameter of the tube, up to 24 readings are taken in different locations across the output of the tube (reference the orange dots in the illustration above as an example). As you might expect, the numbers can vary depending on where in the tube you take the reading, so we take an average of those various readings and that is the CFM rating we publish.

To be certain this was a fair method when comparing our numbers against the competition, we tested their equipment using the same method. In most cases, we achieved the same CFM numbers they publish online and/or in their brochures (for those that publish their CFM ratings).