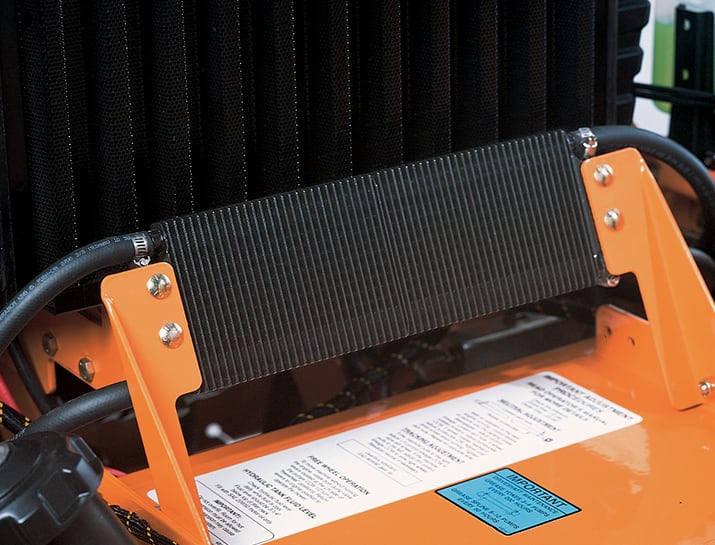

Select Scag® models feature hydraulic oil coolers as standard equipment. Oil coolers are utilized on certain models to keep operating temperatures down and add to the hydraulic system life.

All Scag hydraulic-drive mowers feature dual “closed-loop” hydraulic systems. The right side and left side are separate hydraulic systems sharing only the oil reservoir and the oil filter. Any oil carrying debris encountered in one “closed-loop” system must pass through the 10-micron oil filter before reaching the other “closed-loop” system. This ensures that any debris in either “closed-loop” system would be captured by the filter, reducing potential damage to the other “closed-loop” system. Sharing the oil reservoir and filter makes servicing easy, as you only need to change one filter and maintain one oil reservoir. Features include:

- Increased hydraulic system life.

- Lower hydraulic system operating temperatures.

- Reduced viscosity breakdown due to heat.

- Dual cooler system keeps oil from the left and right side separate.

- Oil cooler position allows for maximum airflow and cooling—engine draws air through the cooler for increased performance.

- Scag uses oil coolers whenever necessary to keep oil temperatures at an acceptable level.